The Problem

Commercial algae production in today’s market relies primarily on tubular and flat plate photo-bioreactors that utilize increased surface area and short light path lengths to increase volumetric cell density. However, these systems create a number of issues (outlined below) that ultimately result in reduced product output and considerably higher operating costs:

Contamination | Overheating | Biofilm Formation | High Consumption of Water | Inefficient CO2 Uptake

The Solution

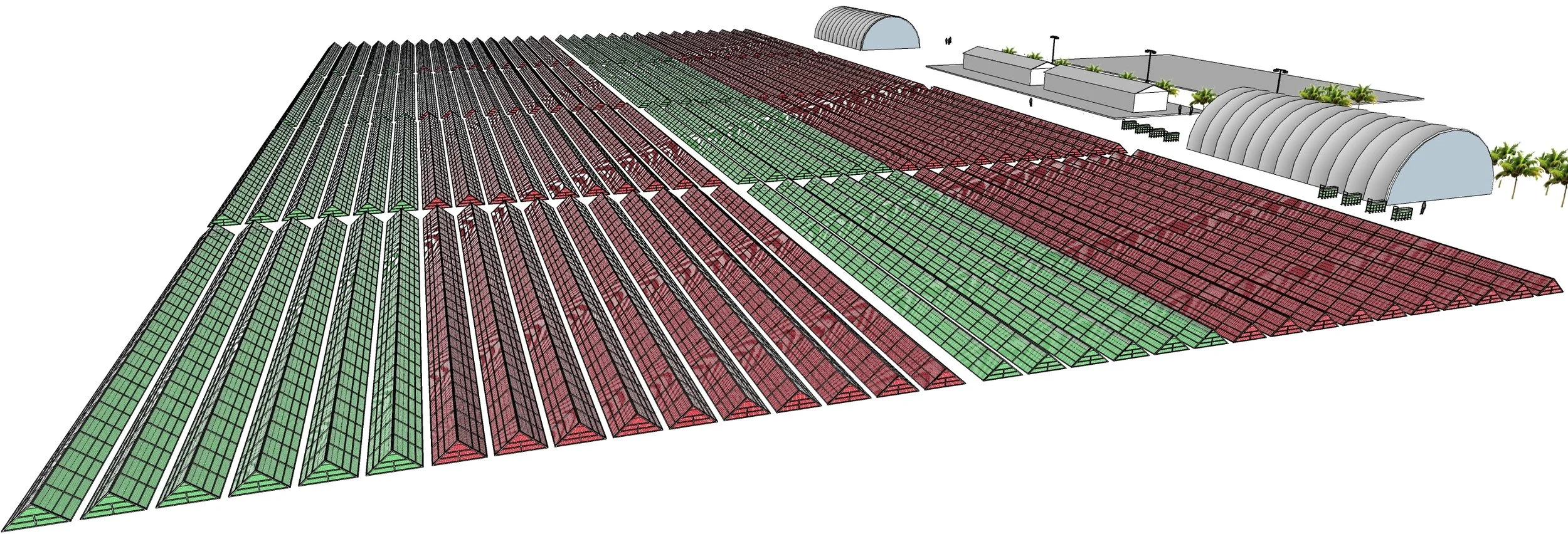

The TriPAR™ (Triangular Prism Algal Reactor) is a closed photo-bioreactor system for algae cultivation developed by PureBiomass. Its unique design specifically addresses the algae production industry’s inability to economically scale closed photo-bioreactors. PureBiomass has achieved scalability by addressing key operational parameters, such as contamination, water consumption, CO2 consumption, and cooling requirements.

The TriPAR™ system is composed of a metal support cage, a plastic bladder containing culture volume, and a sterile harvest apparatus for the continual collection of pre-concentrated culture. This system is equipped with both pH and temperature control options. The live culture is routinely and thoroughly mixed using air sparging. The TriPAR™ is a stand-alone photo-bioreactor system that allows for the sustainable and large-scale production of high-purity microalgae, a staple ingredient among a vast array of consumer products.