TriPAR System

The TriPAR™ is effectively redefining closed system photo-bioreactors, ensuring improved biomass productivity and process reliability through its ecologically aware design.

The Problem

Commercial algae production in today’s market relies primarily on tubular and flat plate photo-bioreactors that utilize increased surface area and short light path lengths to increase volumetric cell density. However, these systems create a number of issues (outlined below) that ultimately result in reduced product output and considerably higher operating costs:

Contamination | Overheating | Biofilm Formation | High Consumption of Water | Inefficient CO2 Uptake

The Solution

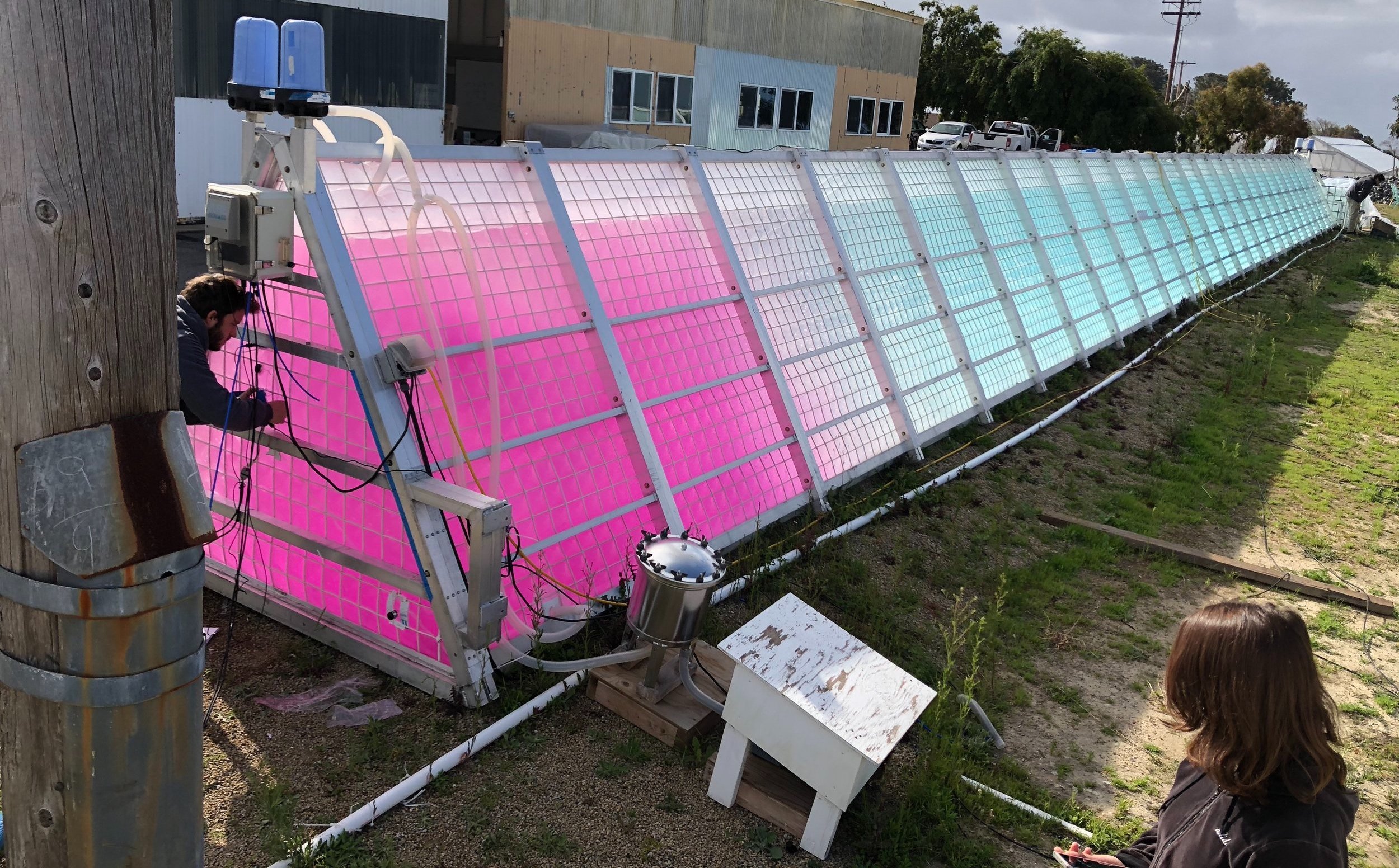

The TriPAR™ (Triangular Prism Algal Reactor) is a closed photo-bioreactor system for algae cultivation developed by PureBiomass. Its unique design specifically addresses the algae production industry’s inability to economically scale closed photo-bioreactors. PureBiomass has achieved scalability by addressing key operational parameters, such as contamination, water consumption, CO2 consumption, and cooling requirements.

The TriPAR™ system is composed of a metal support cage, a plastic bladder containing culture volume, and a sterile harvest apparatus for the continual collection of pre-concentrated culture. This system is equipped with both pH and temperature control options. The live culture is routinely and thoroughly mixed using air sparging. The TriPAR™ is a stand-alone photo-bioreactor system that allows for the sustainable and large-scale production of high-purity microalgae, a staple ingredient among a vast array of consumer products.

Redefining Low-Density Cultivation

The TriPAR™ is effectively redefining closed system photo-bioreactors, ensuring improved biomass productivity and process reliability through its ecologically aware design. The PureBiomass system raises algae growth rates by increasing light penetration into low-density culture. Low-density algae cultivation may seem counter-intuitive, but has proven to be extremely effective in boosting productivity rates. This approach, which relies on our proprietary Harvest Apparatus to remove settled biomass, guarantees a drastically reduced rate of water consumption. The TriPAR™ system also eliminates the usual requirement of close proximity to a carbon source, making the location of production facilities all the more flexible. Carbon present in the atmosphere can sufficiently support moderate yields in a low-density culture. Furthermore, because the TriPAR™ accommodates a greater volume of culture than its high-density counterparts, it has a much greater thermal mass, which eliminates the need for a cooling agent in most moderate climates.

The design innovations of the TriPAR™ system include: minimal or no requirement for carbon supplementation, reduced energy loads for heating and cooling, and significantly improved water conservation, all while maintaining culture purity and high productivity over a small areal footprint. We believe that the TriPAR™ can become the world’s most scalable photo-bioreactor system, and fully support robust aquaculture and biofuel industries.

Included with the TriPAR System:

TriPAR Bag, 15 ports

.Aluminum Frame, W/ PVC Coated/ Galvanized Cage, Polypropylene Tank Bottom, and hardware for assembly

5 - Valve Manifold for System Water Works

Remote WiFi - pH Control with CO2 Solenoid and Rota-meter inside Nema 4 enclosure (Remote control with user interface)

Harvest Apparatus for Harvest and Resuspension w/ HAICU technology, (Harvest Apparatus Interphase Control Unit)

2 - 500 LPM Air Pumps

2 - 0.2 um Air Inlet Filters

4 - Exhaust Air Filters (0.375 um)

Silicone Tubing, Fittings & Clamps

Interested in finding out more info about ordering the PureBiomass TriPAR System? Contact us for more info.